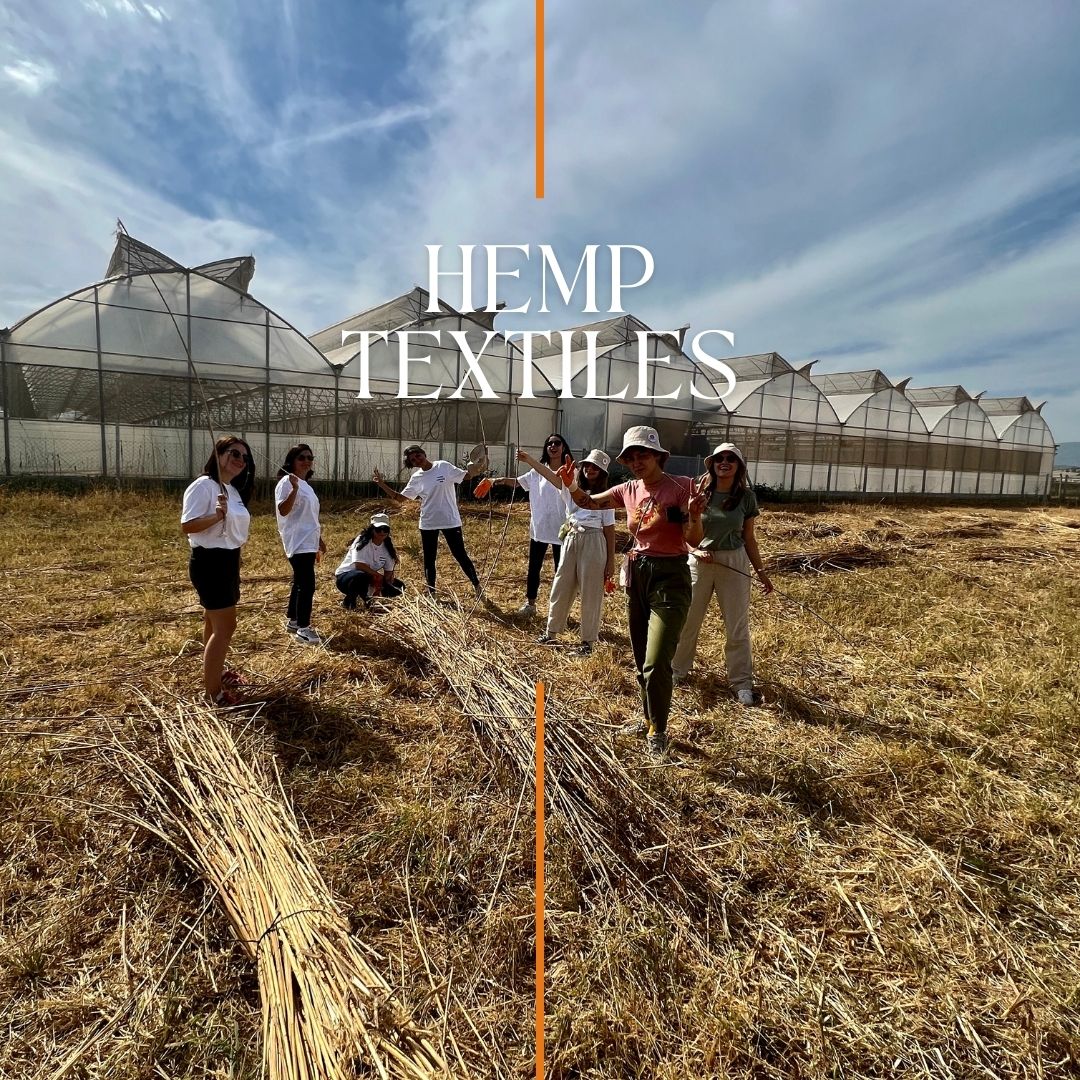

Egedeniz Group’s hemp farm, nestled within 45 km² of our Izmir headquarters, stands as a testament to the remarkable qualities of this plant. As we approach 2024, we are excited to share the journey of Turkish hemp textiles through a one-minute video. This visual storytelling emphasizes hemp’s short life cycle, its positive impact on soil health, and the meticulous processes involved in transforming it into a sustainable textile raw material.

Hemp Textiles Sustainability

Short Life Cycle:

Hemp, with its short life cycle, captivates us with its ability to rapidly grow and mature within months, making it an environmentally efficient choice for sustainable and eco-conscious fashion brands and farmers!

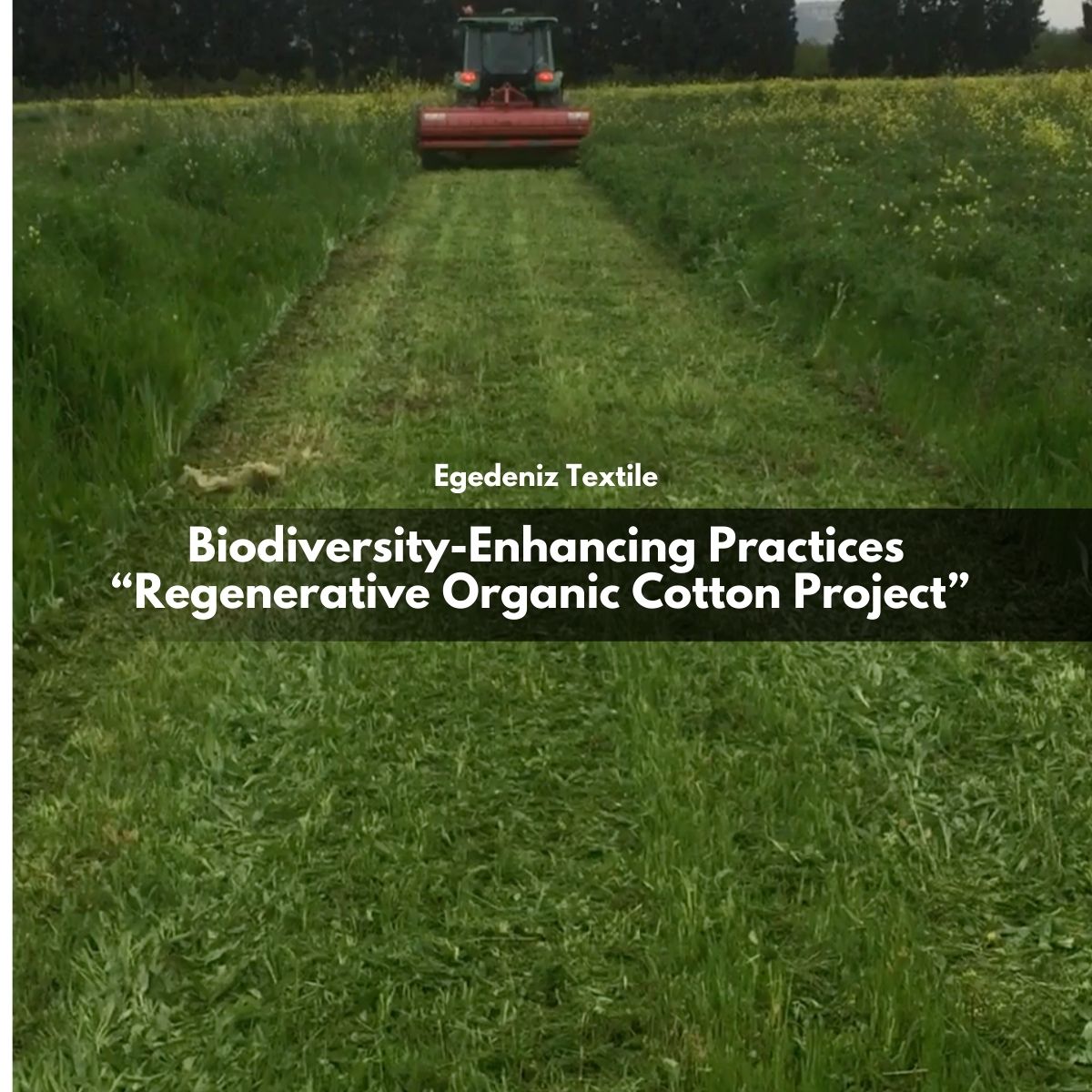

Chemical-Free Cultivation:

Sticking to Egedeniz Group’s sustainability vision, we take pride in cultivating hemp without the need for pesticides and chemicals. This not only ensures a clean and pure textile but also minimizes environmental impact.

Deep Roots and Soil Health:

The deep roots of the hemp plant play a crucial role in enhancing soil health. By increasing soil organic matter, hemp contributes to the overall well-being of the land it grows in.

Water Conservation:

Compared to cotton, hemp has a significantly lower water requirement for growth, making it a sustainable choice that helps conserve precious water resources.

Our Hemp Farm in Izmir, Turkey

Here, regenerative practices take center stage as we grow hemp to harvest fibers improve soil health, and enhance its natural ability to absorb CO2 from atmosphere.

Planting to Harvesting:

In 2023, we planted our hemp seeds in March, and by August, we celebrated the harvest. After carefully leaving the hemp stalks in the field to dry for nearly three weeks, the stage was set for the next crucial steps.

Innovative Processing:

Our commitment to sustainability extends beyond cultivation. Astab Tabacoo Machinery, our esteemed project partner, has developed cutting-edge machinery for separating hemp fibers from the woody parts. This process ensures that we obtain high-quality bast fibers ready for textile production.

Biodegradable Byproducts:

The journey doesn’t end with fibers. Through this process, hemp yields valuable byproducts such as hurd and hemp tow. These biodegradable materials find applications in various industries, including insulation, composites, animal bedding, and construction. We’re delighted to contribute to sustainable design initiatives across diverse sectors. Contact us at info@egedeniztextile.com for getting more info.